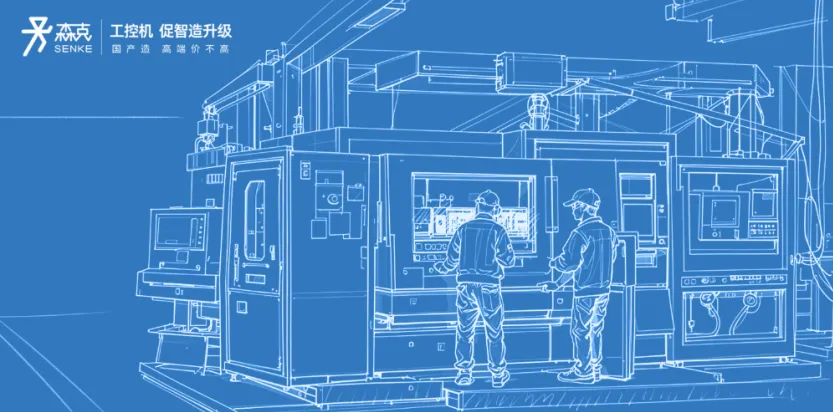

Industrial Panel PC In Different Environments

- Control of Automated Production Lines

In the automated production line for precision machining, the industrial panel pc plays a central control role. It coordinates the actions of each device, such as loading and unloading of robots, processing equipment processing sequence. For example, in an automated production line for precision bearings, the industrial pc ensures that each machining process is carried out according to the predetermined beat and accuracy requirements, improving production efficiency and product.

- Parameter Setting And Adjustmen

When machining small precision parts on CNC lathes, parameters such as cutting speed and feed are accurately set using the industrial panel pc integrated machine. And it can be flexibly adjusted according to the processing material, part precision requirements and other factors, which helps to improve the precision and quality of parts processing.

- Recording of Quality Inspection Data

The E - SOP industrial pc can play an important role in the quality inspection process. Inspectors can use it to record quality data such as part dimensions and surface roughness. For example, when inspecting precision molds, the inspection data is entered into the all-in-one machine and the system automatically generates inspection reports. These reports can be used to trace the quality of the product and also provide data support for subsequent process improvements.

- Remote control of equipment

For some of the precision processing equipment located in special environments or not easy to approach, industrial panel pc can realize remote control. In the ultra-precision grinding workshop with clean requirements, the staff can control the equipment remotely through the industrial panel pc outside the control room, reducing the interference of personnel into the environment, while accurately executing the processing instructions.